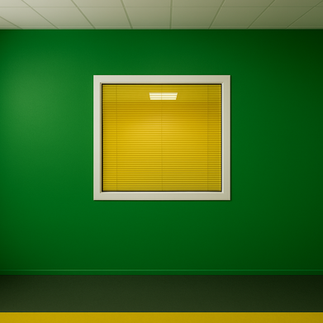

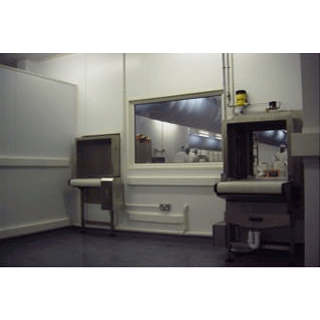

What to Consider When Choosing a Cold Room Window

- Juliet Sidney

- Jul 16, 2025

- 2 min read

Cold rooms are built for performance—designed to maintain strict temperature control, hygiene, and durability. While windows are not always a standard feature, they are essential in certain sectors such as food processing, pharmaceuticals, laboratories, or any environment where visibility, supervision, or natural light is a priority.

Choosing the right cold room window involves more than selecting a size. It’s about insulation, safety, hygiene, and compliance. Here's what to consider.

1. Thermal Efficiency and Insulation

Maintaining the correct temperature is essential in any cold room environment. Windows should match the thermal insulation properties of the surrounding wall panels to avoid heat loss, condensation, or energy inefficiency.

Key points:

Double-glazed glass is often essential

Thermal breaks within the frame can reduce cold bridging

2. Safety and Glass Standards

In many cases, cold room windows should be manufactured from safety glass—particularly in food or healthcare environments where breakage could pose a hazard.

What to look for:

Toughened or laminated glass. However, in general we would always suggest using 6mm clear polycarbonate as a food safe/healthcare solution.

3. Frame Materials and Sealing

The window frame must be robust, resistant to corrosion, and able to maintain a hygienic seal over time. This is especially important in chilled environments with frequent cleaning.

Recommended materials:

PVC for windows, and aluminium for the smaller vision panels.

Real-World Applications

Eurocold supplies high-performance cold room windows for a wide range of sectors including food production, medical, and cleanroom environments. Whether you need a single unit or a full fit-out, we can help you find the right solution.

Request a Quote or Expert Advice

If you’re designing or upgrading a cold room, we’re happy to provide a no-obligation quote or technical guidance or visit our Online Shop

Comments